Have you ever wondered what components comprise our wonderful range of disintegration testers? Or what a disintegration tester actually is? Let us give you a little explanation, and you’ll be well on your way to making a decision as to whether your laboratory requires one.

The primary purpose of disintegration testers is to measure the amount of time it takes a tablet (sample) to totally disintegrate inside a liquid medium. The liquid used in the disintegration tester vessel is often an acidic mixture, designed to replicate the inside of the human stomach. Disintegration testers allow researchers and quality control technicians to ascertain if a tablet does indeed breakdown inside the human body, and how long it takes to do so. This can provide information useful to improving and manufacturing pharmaceutical drugs and also confirm that standards of compliance and regulation are being maintained.

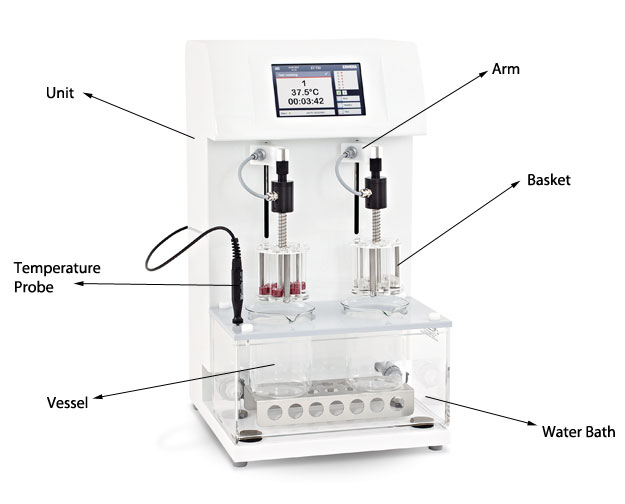

Disintegration testers work by raising and lowering a ‘basket’ in and out of the test medium, for a set period of time, to see if the tablet dissolves or not. The test medium sits inside the vessel, which sits inside a bath of warmed water, used to replicate the temperature of the human body.

The disintegration testers raise and lower the basket in an attempt to create movement, similar to the conditions indie the human stomach, so that the tablet can move about and the test medium circulate around it in a manner similar to inside the body. At no point does the basket raise itself completely out of the test medium, so the tablet is always submerged throughout the disintegration tester’s operation.

Disintegration testers are commonly comprised of a basket, a vessel, a water bath and the actual disintegration unit itself (which operates the basket motion and heats and pumps the water in the bath).

Have disintegration testers evolved?

Traditionally, disintegration testers required a laboratory technician to manually lower the basket into the vessel before the test commenced. It was also common place to have to manually set the teste time, then visually remove and inspect the basket, to see if the tablet had dissolved.

In recent years, automation has become increasingly more desirable, whereby disintegration testers can automatically lower and raise their own baskets into the medium, and in some cases, even determine the exact time of tablet disintegration too.

Total Laboratory Services Ltd can provide your laboratory with brand new disintegration equipment, built by the well know German manufacturer ERWEKA. Our disintegration testers are handmade, durable, reliable and last forever. A class above the rest, if you will. We sell a range of manual and automated disintegration testers, and can happily provide quotations and advise wherever necessary. If that wasn’t enough, our skilled engineers have over 20 years’ experience in the field of laboratory equipment serving, and can install, validate, calibrate and qualify and repair your new and existing disintegration testers with ease. We are fully certified and ready to help.

Contact us to find out more, or click here to view our range of new disintegration testers. Spare parts are also available upon enquiry.