Tablet hardness testers, tablet testers, hardness meter, or whatever you may call them, are a crucial piece of laboratory equipment for any analytical lab. But with so many options to choose from, and so many new labs opening their doors, the question of how they actually work is seldom highlighted.

Tablet hardness testers operate on the principal that it takes a certain amount of force to break a tablet, and this force is then recorded in Newtons, and becomes the hardness value. This is what the lab technicians use to determine compliance and quality control.

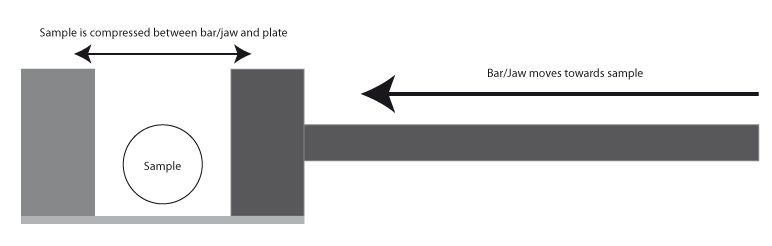

The operation of most tablet hardness testers can be broken down to a simple movement of a bar, or jaw, which compresses the tablet between two hard plates, forcing it to crack under the pressure and thus, determining the force required.

The same motion, from the same bar/jaw can also be used to determine the thickness and diameter, and sometimes length, of the sample as well. This can enable tablet hardness testers to measure up to 4 different parameters of a single sample, using the same single piece of equipment. Of course, when measuring diameter, thickness and length, the bar/jaw does not crush the sample, it stops as soon as the tablet has been pressed between the two plates, and calculates the distances to determine the required results.

Tablet Hardness Testers – Ask the experts.

There are many different tablet hardness testers on the market, all built around this same essential principal, but here at Total Laboratory Services Ltd we only sell ERWEKA, because we believe it to be the best. ERWEKA tablet testers are handmade, of very high quality and durable design, making for a long term, reliable investment piece that will serve your lab well. Take a look at our range of tablet hardness testers here, or contact us for more information.